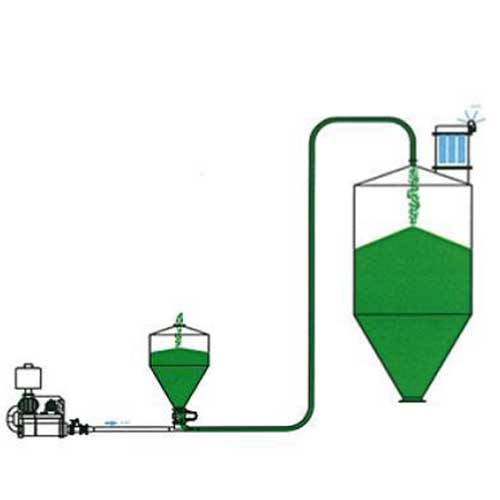

Lean Phase Vacuum Conveying Systems (also known as Dilute Phase) generally use positive displacement (Roots type) exhausters providing up to 50% vacuum to convey materials through a pipeline to the destination where the air and product are separated at a receiving vessel with a filter, or a cyclone. Lower capacity systems are also available which use fans as the prime mover.

The product enters the convey line directly, or if metering is required, via a special feeding device such as a rotary valve or screw-feeder. The product is frequently suspended in the airflow, moving at relatively high velocities depending on the particle sizes and densities. The conveyed product is discharged from the receiving vessel either on a continuous basis by a rotary airlock or intermittently by valves.

Lean Phase Vacuum Conveying Systems are particularly suitable for systems which convey materials at low to moderate capacities over medium distances, from multiple points to a single destination. These systems are versatile and adaptable for different materials and the low operating pressures allow lower cost pipelines and fittings. This method is frequently used for Central Vacuum Cleaning Systems and other applications, which require a reticulated network of vacuum pipes to convey product to a single collection point.

A wide variety of options for system and component design are available to suit particular system requirements, including the following: