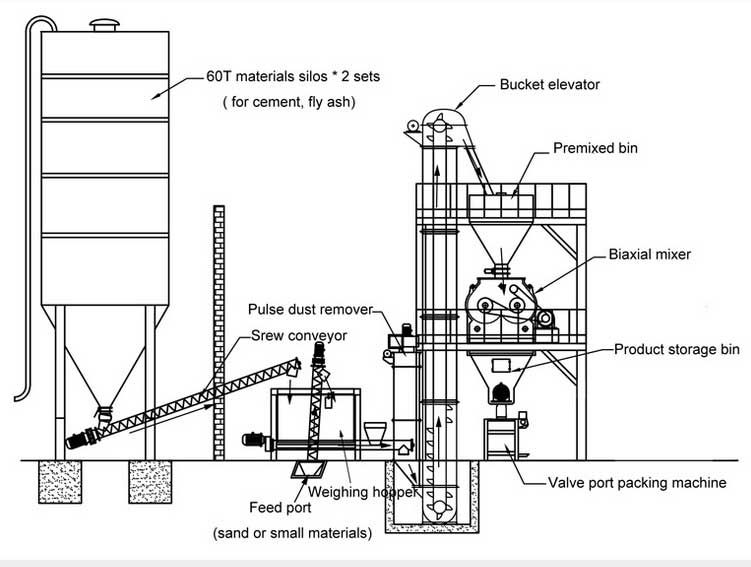

Simple, material after outdoor bucket elevator was promoted to the raw materials warehouse(premix bin), and then delivery the material to the weighing system, then after weighing the material enter indoor bucket elevator through screw conveyor, and then through the screw conveyor into the dry mortar mixer, and then the material falls into the mixer to mixing, mixed materials into finished products bin, you can choose the finished material in bulk or in bags.

A Dry Mix Mortar Plant is a modern facility designed for the production of dry mix mortar, which is a ready-to-use, pre-blended mixture of cement, sand, and other additives. This type of plant ensures high-efficiency production of consistent and high-quality mortar used in construction and renovation projects. Dry mix mortar offers significant benefits over traditional wet-mix mortar, such as improved workability, enhanced strength, and reduced material wastage, making it an ideal choice for applications such as plastering, tiling, and masonry.

The plant typically includes several key components, including a batching system, mixing unit, storage silo, packing machine, and transport conveyors. Raw materials are accurately measured and blended in a controlled environment to ensure uniformity and consistency in the final product. The finished dry mix mortar is then packed and distributed to construction sites, where it is mixed with water before application. With automated control systems, Dry Mix Mortar Plants offer increased production capacity, minimized human intervention, and superior product quality. This makes them a cost-effective and reliable solution for the growing demand in the construction industry.