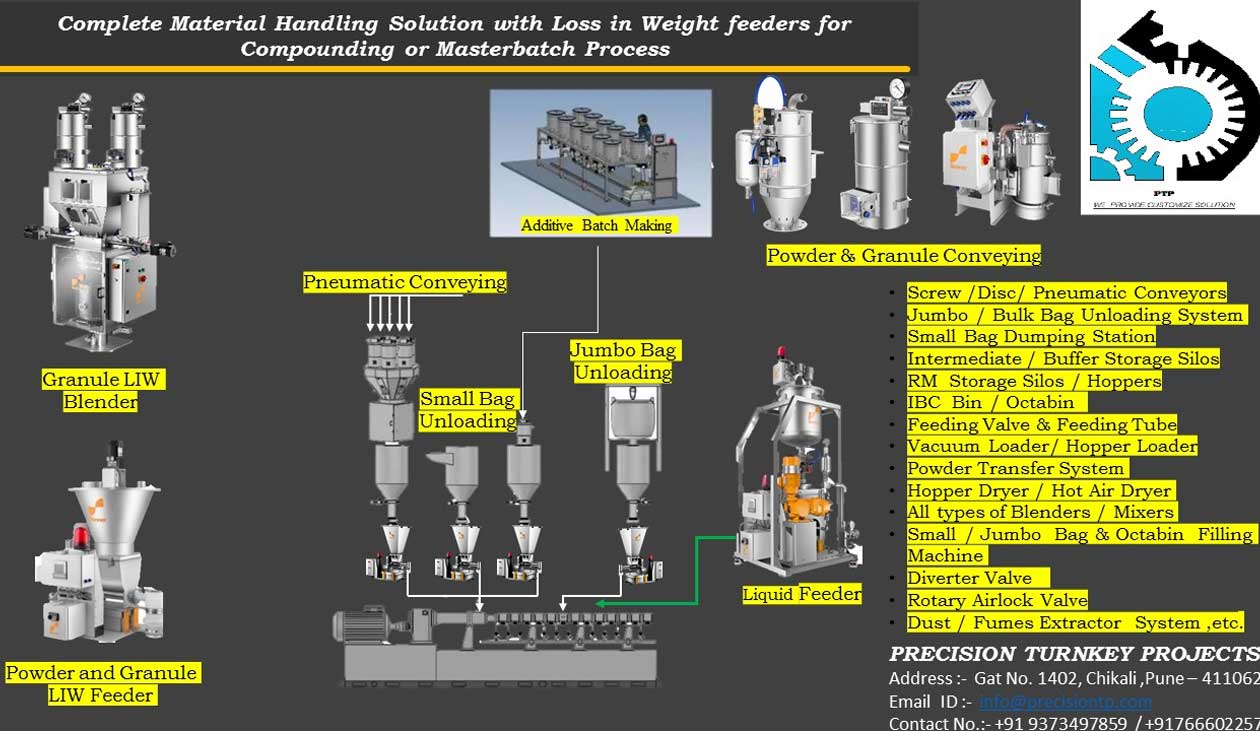

A Compounding / Master Batch Processing Line is a state-of-the-art system used for the efficient blending and processing of raw materials to create custom compounds or masterbatches in the plastics, rubber, and chemical industries. This line is designed to mix polymers with additives, colors, fillers, and other essential ingredients to produce high-quality, consistent, and tailored materials that meet specific industry requirements. The compounding process ensures optimal dispersion of the ingredients, leading to improved product performance, durability, and appearance in end applications such as automotive parts, packaging, consumer goods, and more.

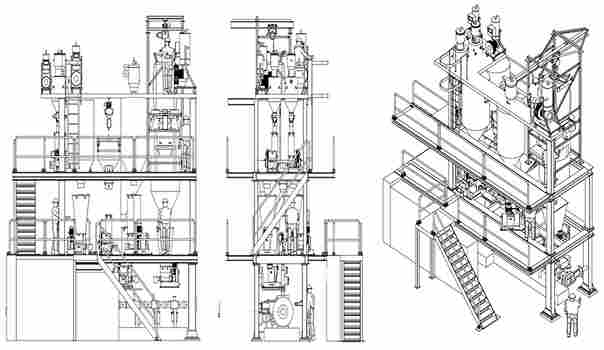

The Compounding / Master Batch Processing Line typically includes high-performance extruders, mixing units, granulators, and cooling systems that are engineered to handle various materials and provide precise control over processing conditions. This versatile line can be customized to produce different types of compounds or masterbatches, such as color masterbatches, additive masterbatches, flame retardant masterbatches, or functional compounds. The efficient operation of this system leads to significant cost savings, reduced material waste, and improved product consistency, making it an essential tool for manufacturers looking to enhance product quality and meet the growing demands of the market.